00:00:10this can range in price from around $200

00:00:12to over 800 that’s a little out of my

00:00:15price range so for this project let’s

00:00:17make this one from common materials and

00:00:19for just a few bucks

00:00:22[Music]

00:00:36this modified transformer is the heart

00:00:38of the spot welder and you might

00:00:40remember it as the metal melter if this

00:00:42doesn’t look familiar

00:00:43check out how this was made and what it

00:00:45can do in some of my other videos I

00:00:47found a practical application for it in

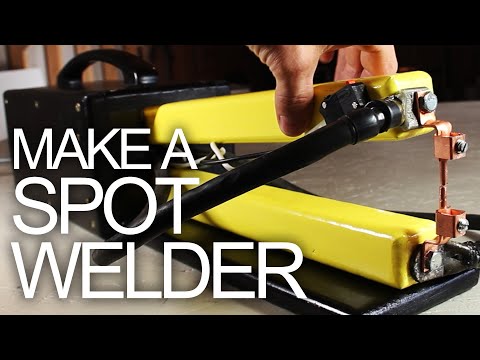

00:00:49making a spot welder like this one to

00:00:51get started I’m gonna measure the base

00:00:52of the transformer and it looks like

00:00:54it’s about four and a quarter inches

00:00:55wide

00:00:56I found a six-foot piece of one by six

00:00:58common board that will be perfect for

00:01:00this using my chop saw I’ll cut two

00:01:02pieces of the board so that they’re both

00:01:0312 inches long then another piece gets

00:01:05cut at 42 inches I’m trimming this piece

00:01:08down with my table saw so that it’s

00:01:10about a quarter inch wider than the

00:01:11transformer base and in this case that

00:01:13measures out at four and a half inches

00:01:15then it gets chopped into three

00:01:16different lengths measuring 24 inches 12

00:01:19inches and 4 inches next I found a 2 by

00:01:222 and I’m cutting the nicest parts of

00:01:24the beam into two pieces measuring 13

00:01:26and 1/2 inches long two other pieces are

00:01:28cut at 4 inches and everything can be

00:01:30placed together to see how it fits

00:01:31that’s the rough idea right there and

00:01:33I’d like to knock down the sharp edges

00:01:35so I found a 3/4 inch rounding bit and

00:01:37routed the appropriate edges to give it

00:01:39a smoother feel these front pieces are

00:01:42gonna be my electrode holders the edge

00:01:44of this scrap piece of wood works as a

00:01:45template to draw a 90-degree angle into

00:01:48the top piece about an inch from the end

00:01:49I don’t have a bandsaw so I’m

00:01:51improvising with my bench vise and a

00:01:53jigsaw to cut this piece out can it work

00:01:55you’ll see what this groove is for in a

00:01:57bit the next part is to cut out the

00:01:59pattern I drew on the back panel so I’m

00:02:01gonna utilize my vise once again and use

00:02:03an 1132 drill bit to cut holes in all

00:02:06the corners so I can get back in there

00:02:08with my jigsaw these holes will be for a

00:02:10switch and a power cord and all this

00:02:12panel needs now are two pilot holes

00:02:13drilled in the appropriate places for

00:02:15the switch I’m thinking I should give

00:02:17this a paint job so all the panels get

00:02:19sanded with an orbital sander then laid

00:02:21out for priming and paint

00:02:22four colors I’m thinking black and

00:02:24yellow with the paint drying I’ve

00:02:26gathered up a few components that were

00:02:28saved from the same microwave I got the

00:02:29transformer from to see all the amazing

00:02:31things that I got from that project make

00:02:34sure you check out my video on salvaging

00:02:35a microwave I found in my neighbor’s

00:02:37trash can I’m gonna use the power cord

00:02:40these wired Spade connectors the door

00:02:42handle and this contact switch aside

00:02:44from the wood the only parts I needed to

00:02:46buy were a single pole light switch with

00:02:48matching cover copper offset terminal

00:02:50lugs a couple of quarter-inch thick

00:02:52screws two small nails and a length of

00:02:55six gauge solid copper wire the copper

00:02:57wire gets marked off in one inch

00:02:58increments and two pieces are cut off

00:03:00using the wire cutter on my pliers these

00:03:03are gonna work as my welding tips the

00:03:05copper lugs have an adjustable screw

00:03:07that can be loosened to insert the solid

00:03:09copper wire when it’s tightened back up

00:03:11it looks like this

00:03:12alright the paint on the wood panels is

00:03:14dry and I’ve added the switch to the

00:03:16back panel to make sure it fits so the

00:03:18next step is to flip it over and press

00:03:19the power cord down into the hole at the

00:03:21bottom the thick piece at the end of the

00:03:23cord prevents it from pulling back

00:03:24through the hole I’m ready to pieces

00:03:26back together so I’m drilling a couple

00:03:28of pilot holes into the bottom and

00:03:29securing the back panel with a couple of

00:03:31screws now the front 2×2 supports are

00:03:34added and the metal melter is placed on

00:03:36the base about an inch back from the

00:03:38supports I’ll add a screw to one of the

00:03:40corners to help keep it in place and at

00:03:42this point I’m ready to rig up the

00:03:43electrical system taking the green wire

00:03:45from the power cord I’m stripping open a

00:03:47gap in the plastic to expose the bare

00:03:49cord this will wrap around the grounding

00:03:51screw on the power switch the end of the

00:03:54wire has a hole I can use to insert

00:03:56another short screw and work that down

00:03:58into the opposite corner of the

00:03:59transformer base not only does this

00:04:01secure the metal melter in place it also

00:04:03grounds out the transformer core at the

00:04:05same time okay I’ve exposed the copper

00:04:08on the black wire and that’ll get

00:04:09connected to the bottom terminal of the

00:04:11power switch and screwed down tight

00:04:12this salvage Spade connector still fits

00:04:15onto one of the Transformers primary

00:04:16terminals so with that on the other end

00:04:18of the wire can be connect

00:04:20to the top terminal of the power switch

00:04:21now the switch can be screwed down

00:04:23permanently and a cover plate added to

00:04:25protect from electric shock and to make

00:04:27it look nice

00:04:27the other Spade connector that was

00:04:29salvaged goes on the left terminal of

00:04:31the primary coil and we could finish the

00:04:33electrical here but I want to add one

00:04:35more switch for convenience

00:04:36this switch still has the original wires

00:04:38and connectors from the microwave and

00:04:40I’ve just added a wrap of electrical

00:04:42tape to make sure I don’t get shocked

00:04:43while touching it I’ll strip the end of

00:04:45the white wire and twist it together

00:04:46with the other white wire coming off the

00:04:48primary then use a wire nut to cover the

00:04:51connection now the black wire is joined

00:04:53with the white wire coming from the

00:04:54power cable and the electrical system is

00:04:56complete I added this microwave door

00:04:58handle to the top panel and I’m screwing

00:05:00it on to see how it holds up the

00:05:02alignment looks good when I pick it up

00:05:03it seems to support the weight without

00:05:05any problem alright with the cables

00:05:07laying out the front it’s time to close

00:05:09up the side panels and I’m doing that by

00:05:11drilling holes and adding six screws on

00:05:12each panel to make sure it’s held

00:05:14securely the next step is to construct

00:05:16these electrode holders I chose to use a

00:05:193/16 bit to drill a hole into both tips

00:05:21of the two by twos which you can see got

00:05:23painted yellow the hole is big enough to

00:05:25prevent the wood from splitting when

00:05:27these screws go in yet small enough to

00:05:29hold them in secure this is the top

00:05:31piece and I’m going to add a switch to

00:05:32the side about half an inch from the tip

00:05:34it gets set at a slight angle and the

00:05:36two small nails are hammered down into

00:05:38the holes already in the switch now the

00:05:40two beams can be slid into the front of

00:05:42the casing with one under the wire and

00:05:43the other over top to secure them in

00:05:46place I’m using some scrap wood to keep

00:05:48them an equal distance apart as I drill

00:05:50a hole through the side of the casing

00:05:51and into the beam I’ve pushed a nail

00:05:53into the hole and now you can see this

00:05:55top piece is able to pivot freely it

00:05:57should be obvious now why we needed that

00:05:59notch near the base the bottom beam also

00:06:01gets a hole drilled on either side as

00:06:03well as its own set of nails to keep it

00:06:05from sliding around the welding tips can

00:06:07be attached now so we push one of the

00:06:09hex screws through the hole in the lug

00:06:11and then join it to the right side cable

00:06:13that gets tightened securely into our

00:06:15pilo hole and all that gets repeated on

00:06:17the top

00:06:18the misalignments can be fixed by

00:06:20bending the lugs slightly inward and now

00:06:22we’ve got perfect contact to finish this

00:06:24off I’d like a way for the top beam to

00:06:26stay suspended on its own so to address

00:06:28the challenge I’ll add a couple of

00:06:30screws and a thick rubber band the

00:06:32system is finished my very own spot

00:06:34welder and for less than $10 in

00:06:36materials let’s see if it works

00:06:38power cord plugs in and with the

00:06:40electrode tips touching I’ll press the

00:06:42button to engage but nothing’s happening

00:06:44well that’s because the safety switch is

00:06:46still off let’s try it again this time

00:06:48when I press the button the system hums

00:06:50and when the tips touch I see the Hiab

00:06:52sparks I was hoping for I don’t have any

00:06:54sheet metal handy so I decided to try

00:06:56using these washers for my first

00:06:57experiment the pressure holds them in

00:06:59place hands-free and with the system

00:07:01energized it only takes about three

00:07:03seconds to fuse them together

00:07:04I’m trying it again with a third washer

00:07:07being careful not to touch these because

00:07:09they’re extremely high surprisingly it

00:07:11even worked on thicker welds like

00:07:13melting a washer to this steel spike

00:07:15trying to break them apart by hand was a

00:07:17fruitless effort so I tried using pliers

00:07:20and even that was a bit of a challenge

00:07:21but I got it that just goes to show the

00:07:24welds are pretty strong a feature I

00:07:26really like about this design is that

00:07:27the electrode holders can be removed

00:07:29allowing the user to extend the welders

00:07:31reach and access difficult angles they

00:07:34go back in as easily as they came out

00:07:36and all it takes to secure them back in

00:07:38place is a little wiggle and the

00:07:40replacement of the locking nails the

00:07:42elastic band is easy to replace and it’s

00:07:44doing a great job providing back tension

00:07:46after I make a connection

00:07:48I tried welding a couple of iron nails

00:07:50in an X pattern and since the heat was

00:07:52concentrated in the center it didn’t

00:07:54burn my fingers the power of the metal

00:07:56melter is still evident in the way the

00:07:58iron is boiling on this nail and if

00:08:00allowed to continue the nail melts down

00:08:02into a little ball of liquid metal when

00:08:05it’s time to replace the electrode tips

00:08:07just loosen the tensioner remove the

00:08:09spent electrode and replace with a fresh

00:08:11piece of your copper wire if you do it

00:08:13this way you can get about 12 tips for a

00:08:15buck because the wire is not that

00:08:16expensive well now you know how to make

00:08:18my version of a spot welder from easily

00:08:20accessible and low-cost parts if you

00:08:23like this project perhaps you’ll like

00:08:24some of my others check them out at the

00:08:26king of random calm

00:08:37you

”